DIY Cornice Board: How to Make a Fabric Covered Cornice Box for your windows! See the full step-by-step tutorial on how we built our scalloped window valance for our girls room and covered it in fabric. See what tools, materials, and tricks you can use to do this and how to mount the cornice to your wall!

DIY CORNICE BOARD

Jump ahead to...

If you’ve been around awhile, you’ve probably seen my Window Valance Box that we installed in our nursery several years ago. It is still one of my favorite DIY window treatments to date and provides a lot of bang for the buck! Nothing elevates a room like good window treatments! But, they don’t have to be expensive! We made this with some simple MDF board, batting, and 2 yards of fabric (and we had some leftover so we could make a throw pillow!)

(see the rest of the girls’ DIY bunk room here!

We hung this cornice box in our girls’ shared bedroom. Our two oldest girls (ages 7 and 3) share a bunkroom and we wanted a window treatment that was beautiful; but, wouldn’t interfere with the built-in bookcases. This simple scalloped cornice board really finishes the room off!

Related: How to Build a Built-in Bookcase

HOW TO DESIGN A SCALLOPED CORNICE BOARD

When sizing a cornice there are a couple of key design rules I try to keep in mind:

1. The Cornice Board should be mounted 1″ below the ceiling:

Our ceilings are only 8 ft. tall, so I like to add height wherever I can. Personally, I like the top of the cornice to come right up to 1” below the ceiling. This helps draw your eyes upwards and makes the ceilings feel taller than they really are. Any higher and it’s hard to maneuver the box.

2. The Cornice Box Should Hide Any Unsightly Blinds

The cornice should be just low enough to cover the top of the window frame and any other window treatments (such as shades or blinds) that you want to cover. We had to move our faux wooden blinds up over the window so closed they would hide behind the cornice box.

These should be just barely covered up when viewing the window at standing height.

3. Don’t cover up too much window–remember you want to let the light in!

You don’t want the cornice to cover any more of the window than necessary but you also don’t want to see the blinds underneath – it’s a balancing act. To size the scallops, it’s really dependent on the size and scale of the window and room.

For this window, we decided on three scallops with a 24” radius and 3 inches of reveal between the scallops.

4. Cornice Board width accounts for window trim and curtain rods

Last, the cornice needs to be wide enough to clear the window casing trim and deep enough that there is enough room for the blinds or curtains underneath. Ours ended up being 72″ wide by 20″ tall by 5″ deep.

See how we built these DIY built-in bunk beds here!

PROTOTYPE A CORNICE BOARD

If you’ve read my blog for a while I probably sound like a broken record here, but we almost always prototype anything new we are going to build – especially if there is a design element we’re not totally sure about or if it’s something that will be expensive or time consuming to change after we’ve built it.

Prototypes do a couple of things for us – first, they confirm what the design element will look like in real life without investing much time/effort upfront. If we don’t love it, it’s easy to make changes at this point until we do. In fact, we consider it a good thing if we do make changes at this point because it means we saved ourselves time/money/headaches had we moved forward with the design.

Second, they confirm the design will actually fit the intended space. In the case of the scalloped cornice, we marked out the location of the top of the window casing on the back of the prototype so we could confirm the l-brackets used to mount the cornice to the wall would not hit the window casing.

For this DIY cornice board we built two prototypes first, a paper one to work out the proportions of the scallops. We revised this one a couple of times until the scallops felt right.

Next, we made a cardboard mock-up that we could hold in place and get a real feel for what the cornice would look and feel like in the room. We loved the way it felt so we were comfortable and confident moving forward to building it out of wood!

HOW TO BUILD A CORNICE BOARD WITH SCALLOPS

*affiliate links have been used at no cost to you please see my complete disclosure policy here

Materials

- Fabric- we used 2 yards of this fabric

- Batting- we used 2 yards of batting

- T-50 Staples 3/8″

- ½” MDF

- L-Brackets

- 1-¼” drywall screws

- 2” drywall screws

- Wood glue

Tools

We built this cornice out of ½” MDF. In reality, this could be built from just about any sheet good you have on-hand – or even a mixture of scraps (which we did on our nursery valance box.)

HOW TO BUILD A WOODEN CORNICE BOX:

1. Cut out the rectangular pieces of wood

Often you can ask someone at your home center to cut the pieces to your dimensions for a small fee. This can be a great option if you don’t have a table saw. It’s also a good option if you don’t have a huge car or truck to lug home a full 4×8 sheet of wood.

For our cornice we didn’t actually have one piece of ½” MDF big enough for the whole front face, so we used two smaller pieces joined together. To join the pieces we glued and nailed two backer-pieces to the backside of the front face. We used two pieces so they wouldn’t get in the way of the cross-brace that would need to be attached later. I wouldn’t necessarily recommend doing it this way because it complicated the build a bit, but it proves you can often make do with what you have on hand.

2. Mark out the scallops using a compass to draw the arcs

With the front face of the cornice cut to size, the next step was to mark-out the scallops. We first measured and marked the center points of the circles that make each of the scallop arcs. You can see that the center point of each arc is actually on the workbench – so we clamped the cornice to the table so it wouldn’t move, and marked the center points right on the workbench.

We used a compass to draw the arcs. You could also use a scrap of wood with two holes drilled in it spaced apart at the radius of the circle. You could also use a piece of string or a tape measure.

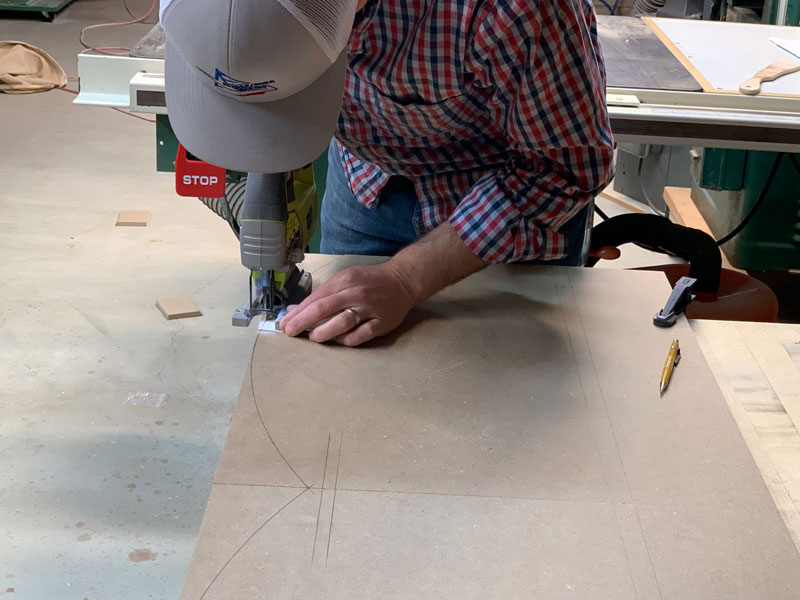

3. Cut the scallops with a jigsaw

Once the scallops were marked, we carefully cut them out with a jigsaw trying to follow the curve smoothly and let the saw to the cutting Pro tip: if you push too hard when cutting a curve with a jigsaw, it causes the blade to bend off to the side and gives you an uneven cut. Once the curves were cut we smoothed them out a bit with some 120 grit sandpaper – it doesn’t need to be perfect here since it will be covered up with batting and fabric eventually.

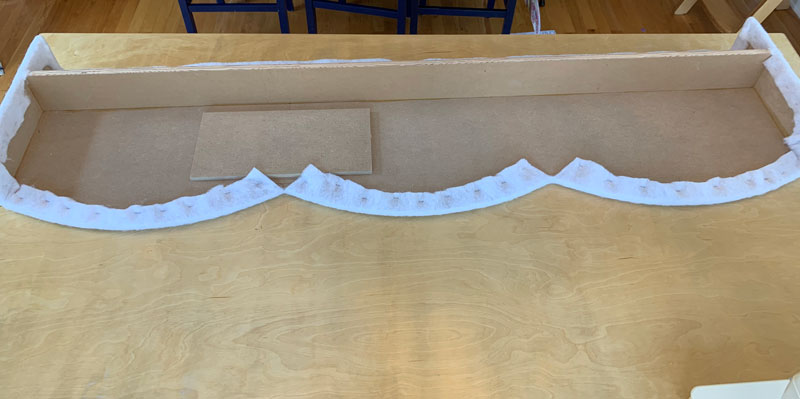

4. Assemble the sides and cross-brace

We used a combination of wood glue, 18ga. brad nails, and 1-¼” long drywall screws. We attached our cross-brace 5 inches down from the top of the cornice, and the sides were cut to be flush with the top and bottom. Once the glue dried, we sanded all the edges and corners with 120 grit sandpaper so there were no sharp points that might poke through the batting or fabric later on.

HOW TO COVER CORNICE BOARD WITH FABRIC

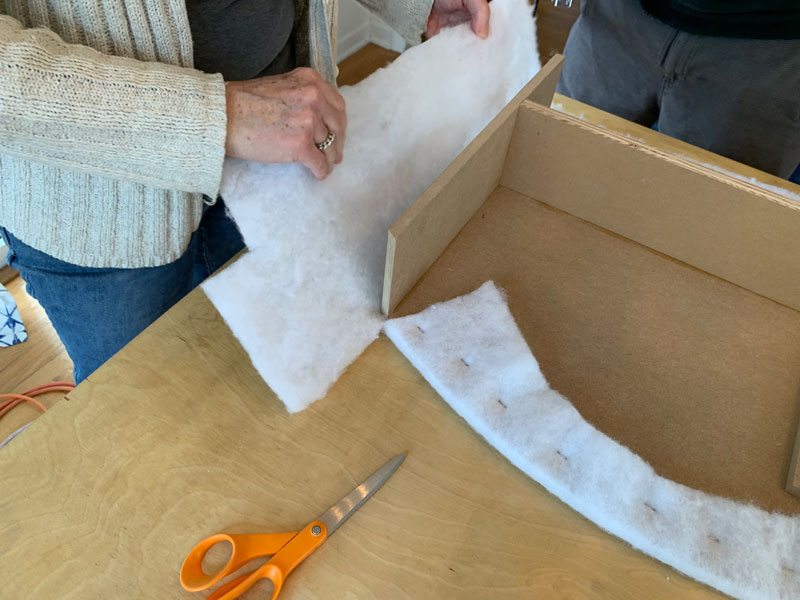

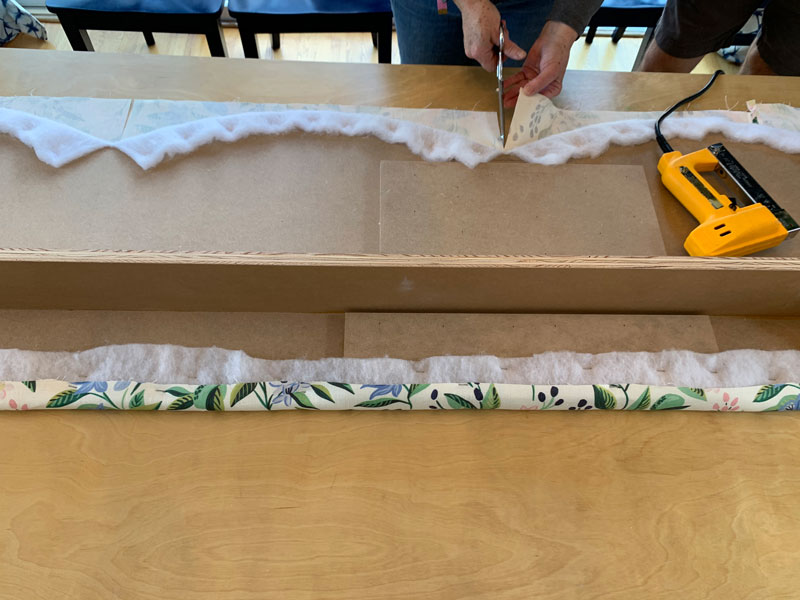

1. Cut a piece of batting larger than the cornice board by 2-3″ on each edge.

We cut a piece of batting out that was larger than the surface to be covered by about 2-3 inches on each edge including the sides – this was to give plenty of extra to staple to the backside of the cornice.

2. Make a slit in the batting at the corners between the scallops (don’t cut all the way to the corner.)

3. Fold batting over and staple to the back of cornice board. Repeat for each scallop.

4. Fold and staple batting along the top edge.

(While doing this Take care that the batting was pulled at a consistent tension so it laid smooth on the front face.)

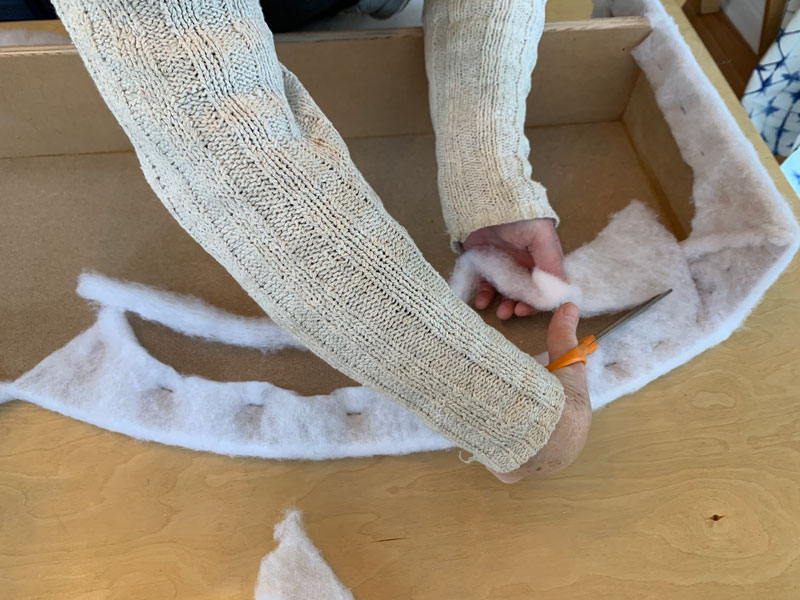

5. Fold, trim, and staple sides and corners of DIY cornice board.

To trim the corners we cut a slit into the corner and folded the batting over itself and stapled it in place. If there was any extra overlapping batting that would have been too thick to staple, we simply trimmed it out. The goal here is to have smooth batting on the visible front and edges of the cornice only – everything else is hidden!

6. Trim any excess batting within an inch or two of staples. This will ensure your DIY cornice board is round enough around the edges which will make it look more professional.

7. Add the fabric covering:

Unfortunately for us, the pattern on our fabric was oriented in a way such that we could not simply cover the cornice with one piece of fabric (or the birds would have all been facing sideways!). To account for this, we opted to seam the fabric to create one piece which was long enough to cover the entire cornice, with the pattern facing the correct direction.

The seams also needed to have the pattern match-up perfectly so they wouldn’t be noticeable. To make things even more difficult on ourselves, we decided to make two seams so they would be symmetrical on the finished piece instead of just one (which would have been off to one side – in hindsight, this step was probably unnecessary, but it looks great and no one has ever noticed the seams)! The final product is one very professional-looking DIY Cornice Board!

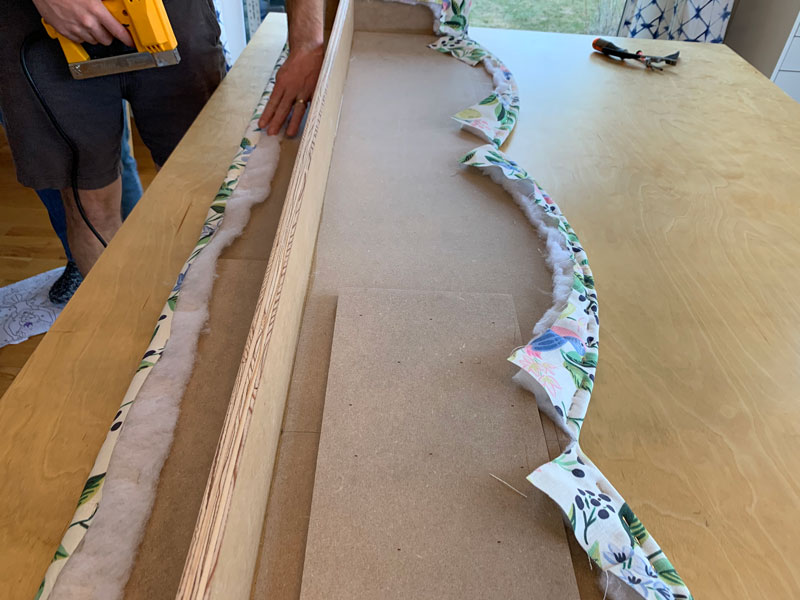

8. Staple fabric to the cornice:

We followed the same steps as before with the batting, except first we put a few staples along the top edge to hold the fabric centered and straight while we worked on the scallops. Again, we cut slits into the corners making sure not to cut too deep or the slit would show through from underneath.

9. Trim excess fabric and get cornice ready to hang on the wall.

HOW TO MOUNT CORNICE BOX TO WALL

To mount the cornice to the wall, use heavy-duty L-brackets.

Most windows have a header above them which means there is solid wood all across the window opening which is perfect for attaching the L-brackets. Verify this with your stud finder (or locate studs to screw your brackets into).

We used 2in. deck screws to attach our L-brackets to the wall. The key here was to make sure the top of the brackets were level and an equal distance down from the ceiling – so we made sure to measure and check twice. We positioned the brackets so the finished cornice would be about 1” below the ceiling.

To attach the cornice, to we simply set it on top of the L-brackets and drove a couple of screws up through the bracket and into the cross-brace.

And the final result…

We couldn’t be happier with how our DIY cornice board turned out! It hides the girls (necessary) but unsightly faux wooden blinds and ties the scallop theme in well with the rest of the room! The cornice design works particularly well in a kids’ room as there are no curtains within kids’ reach!

FAQs on WINDOW CORNICES & DIY CURTAINS

What’s the difference between a window valance and a cornice box?

The primary difference between a window valance and a cornice box is that cornice boxes are made out of wood. Sometimes they are covered in fabric–other times not. While, there is a difference between the two, most people don’t know the difference and use them interchangeably. A fabric-covered cornice box is unique in that it has no loose fabric underneath (unlike a window valance.)

What is a window valance?

A window valance is a type of window treatment–the uppermost part which typicallly covers blinds. It is made out of fabric and can be combined with curtains underneath or left bare. It is also called a pelmet box in the UK.

What is a cornice box or a window cornice board?

A cornice box or a cornice board is a hard-top box around the top of a window. It typically hides window treatment hardware underneath (like blinds).

Want to see more DIY Curtain posts? Check out our whole library here!

>”>

>”>